Double Flap Gate Valves - CL & FL Series Specifications

Range of applications:

Temperatures to 1000°C

Differential pressures to 102 Kpa where positives below

Abrasiveness - Some of the most abrasive materials are comfortably handled

Lump Size - Depends upon valve opening size

Openings to 600mm square and 900mm x 450mm in operation

Features

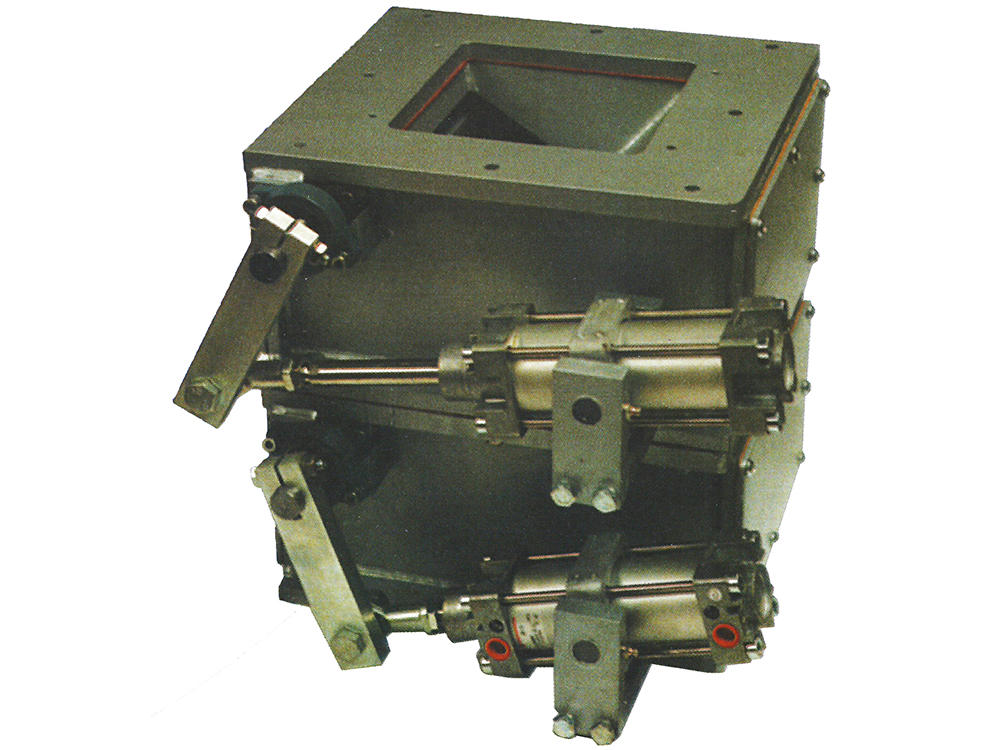

Dual access covers outboard bearings;

Adjustable packed shaft seals as standard;

VDMA ISO standard cylinders;

Removable seat and flap with valve in-situ;

Regrindable seat and flap;

All metric standard components.

Actuation options

Linear Pneumatic Cylinders;

Rotary Pneumatic Actuators;

Electric motor via cams;

Electric motor via push rods;

Gravity or Manual;

Hydraulic actuators.

Material of construction

Valve bodies have been made in Cast Iron, Cast High Nickel Alloys, Cast Aluminum, Fabricated Stainless and Carbon Steels;

Seats and Flaps are generally made from Cast Hi-Chrome Iron or Stainless Steel;

All other components to suit process conditions to give maximum life and reliability.

Optional Equipment

Sequence control with mini-PLC;

Flap positioning indication through shaft mounted contact limit switches, non-contact proximity switches or cylinder mounted reed switches;

Heat shields;

Shaft air cooling and shaft extensions for valve insulation in high temperature applications;

Purged high efficiency shaft seals.

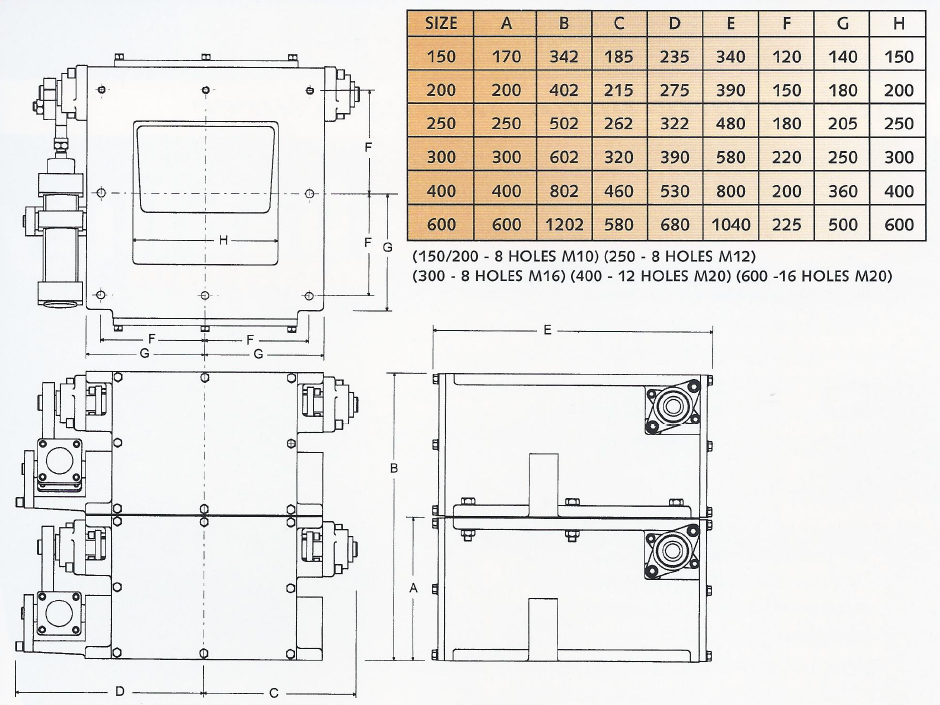

Double Flap Valve dimensions, click for larger image.

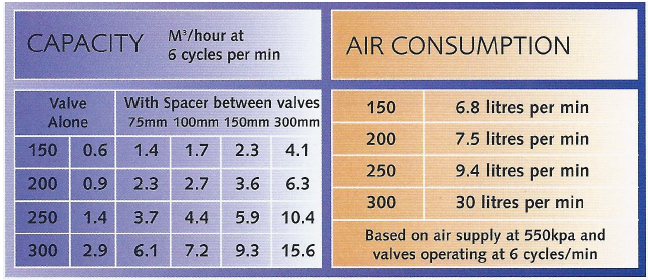

Double Flap Valve Capacity (1000kg/m³) and Air Consumption.